Product Description

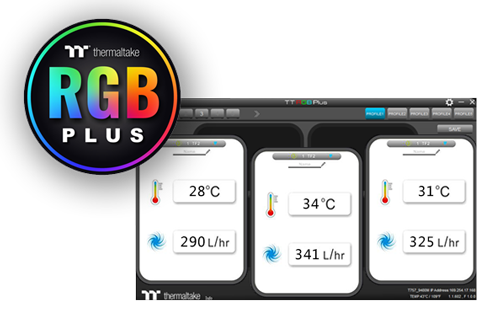

The optimized Pacific TF2 not only reflects the temperature and the volume of flow on the screen itself but also can be tracked on TT RGB PLUS software, providing real-time information to the users.

Note:

*The information shown may include latency between TT RGB PLUS and TF2.

*TF2 Temperature and Flow Indicator only supports TT RGB PLUS software , and users must connect the specific controllers of the following water block models.

Designed with an easy, user-friendly setup, the Pacific TF2 Temperature and Flow Indicator allows users to easily track their temperature and flow rate by simply connecting the power cable to the unit.

*Note:

1. Please check your system immediately to prevent any hardware damages when the alert is triggered. The default alarm temperature is 45℃ and 60(L/hr) for coolant flow.

2. Please check the melting point or maximum operating temperature of each cooling component before you manually adjust the temperature threshold.

3. The default water flow is 60(L/hr). If the alarm beeps, please check the system immediately to prevent any damage.

Thermaltake recommends the following steps to be taken before using the Pacific series radiators and water blocks

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant, it may harm your loop and reduce performance.

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse and dry. This will ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after completing your water loop setup

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while preventing the entire cooling system – copper, brass, nickel, aluminum, and steel – from corrosion.

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushing the coolant into the loop.

- DO NOT let the pump run dry, when there is no liquid entering the pump turn off your power immediately.

- Fill the reservoir to the top as it will prevent air from going into the pump.

- If necessary tilt the system slightly from side to side to bleed the air out of the loop.

- Place some paper towels under fittings and joining points to test for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed the air out of the loop.

- Before starting, flush out your system correctly to prevent any coolant or unwanted particles sticking to your tubes, radiators and other cooling components.

- Coolant might fade over time.

Reviews

There are no reviews yet.